Home / Product Line

Agricultural Machine Supplier

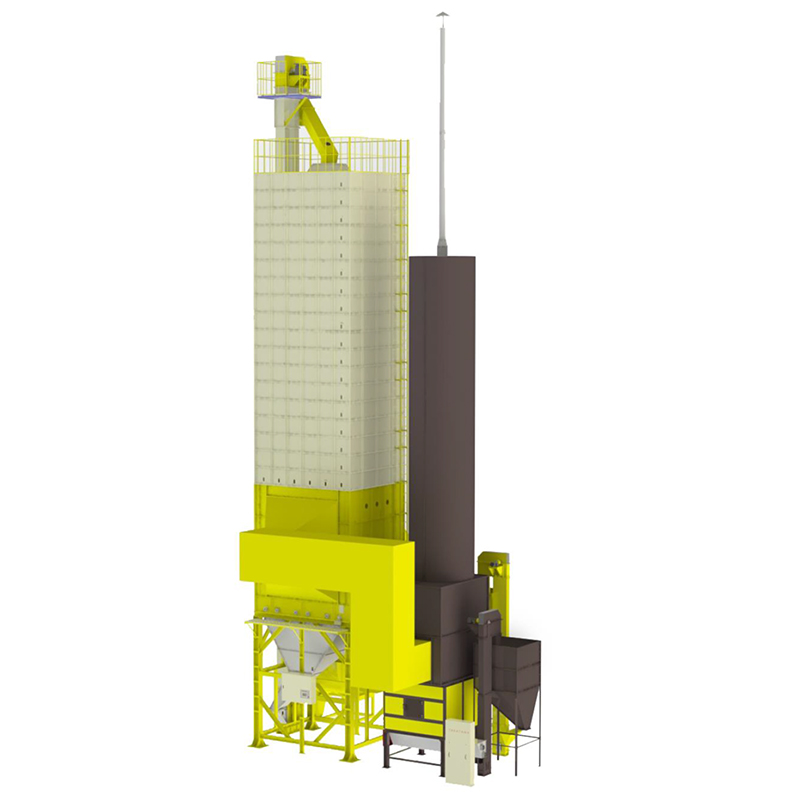

High-tech Grain Dryer and Husk Furnace

Husk machine

High-tech Grain Dryer and Husk Furnace

The working principle of High-tech Grain Dryer and Husk Furnace:

H1 temperature control and even baking

TW GRANDEUR MACHINERY 's High-tech Grain Dryer and Husk Furnace achieve uniform

baking through temperature control technology. This ensures that the rice grains

are not affected by temperatures that are too high or too low during the baking

process, maintaining their optimal nutritional value.

H2 long-term use and durability

This dryer has a sturdy design and excellent durability. It operates for a long

time and requires minimal maintenance, saving maintenance costs and time.

H3 is easy to operate

Using TW GRANDEUR MACHINERY 's High-tech Grain Dryer and Husk Furnace is very

simple and does not require complicated operating procedures or special skills.

This makes it ideal for agricultural users and processing plants.

H4 Reduce drying costs

The efficiency of this dryer means you save energy and costs during the drying

process. It can complete drying tasks quickly and evenly, making your production

line more competitive.

Improve rice quality:

H1 retains nutritional value

TW GRANDEUR MACHINERY 's High-tech Grain Dryer and Husk Furnace can retain the

nutritional value of rice grains during the baking process. This means you can

provide healthier, more nutritious rice grains to your customers.

H2 improves taste

This dryer not only preserves the nutritional value, but also improves the taste

of the rice grains.

cut costs:

H1 Reduce energy consumption

Due to their high efficiency, TW GRANDEUR MACHINERY 's High-tech Grain Dryer and

Husk Furnace can reduce energy consumption and save your production costs. It’s

also more environmentally friendly.

H2 Reduce labor costs

The easy-to-operate design means you don’t need a lot of labor to run this

dryer. This saves your human resources costs.

TW GRANDEUR MACHINERY 's High-tech Grain Dryer and Husk Furnace are amazing

pieces of equipment that not only improve the quality of rice grains, but also

save production costs. Whether you are an agricultural user or a food processing

plant, this dryer is worth your consideration. Its durability, ease of

operation, and cost-saving benefits will bring tremendous value to your

business.

TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk Furnace

Rice husk furnace dryer

Heat-conducting element design features extra powerful heating efficiency.

The working principle of High-tech Grain Dryer and Husk Furnace:

H1 temperature control and even baking

TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk Furnace

achieve uniform baking through temperature control technology. This ensures that

the rice grains are not affected by temperatures that are too high or too low

during the baking process, maintaining their optimal nutritional value.

H2 long-term use and durability

This dryer has a sturdy design and excellent durability. It operates for a long

time and requires minimal maintenance, saving maintenance costs and time.

H3 is easy to operate

Using TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk

Furnace is very simple and does not require complicated operating procedures

or special skills. This makes it ideal for agricultural users and processing

plants.

H4 Reduce drying costs

The efficiency of this dryer means you save energy and costs during the drying

process. It can complete drying tasks quickly and evenly, making your production

line more competitive.

Improve rice quality:

H1 retains nutritional value

TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk Furnace

can retain the nutritional value of rice grains during the baking process. This

means you can provide healthier, more nutritious rice grains to your customers.

H2 improves taste

This dryer not only preserves the nutritional value, but also improves the taste

of the rice grains.

cut costs:

H1 Reduce energy consumption

Due to their high efficiency, TAKAYAMA High-tech Dryer Indirect air heating &

high Efficiency Husk Furnace can reduce energy consumption and save your

production costs. It’s also more environmentally friendly.

H2 Reduce labor costs

The easy-to-operate design means you don’t need a lot of labor to run this

dryer. This saves your human resources costs.

TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk Furnace

are amazing pieces of equipment that not only improve the quality of rice

grains, but also save production costs. Whether you are an agricultural user or

a food processing plant, this dryer is worth your consideration. Its durability,

ease of operation, and cost-saving benefits will bring tremendous value to your

business.

Husk Furnace

In modern

society, the efficient use of energy resources has always been a key issue. The

increasing requirements for environmental protection and energy conservation

have also prompted the continuous upgrading of energy production technology.

A breakthrough product, the Husk Furnace produced by TW GRANDEUR MACHINERY is a great technological innovation in the field of energy production.

The

Husk Furnace is a kind

of combustion equipment specially designed for bran raw materials. Its operating

principle is extremely unique and efficient. First, the coarse bran is

transported through a screw feeder, and the frequency converter controls the

speed and is controlled by the instructions of the PLC to ensure that the

combustion volume matches the temperature requirements. When the temperature is

insufficient, the system will automatically speed up the feeding speed to ensure

that the combustion reaches the required temperature. On the contrary, when the

temperature exceeds the set value, the system will reduce the feeding speed to

achieve temperature balance. This intelligent control enables

Husk Furnace to burn

efficiently and save energy.

The gas

generated during the combustion of coarse chaff will not be wasted, but will be

blown out by the combustion fan, and then burn smoothly into a flame. This not

only reduces gas emissions, but also makes full use of this resource. Part of

the burned air must be discharged from the chimney to ensure that fresh oxygen

can smoothly enter the combustion fan. This process not only ensures combustion

efficiency, but also reduces adverse effects on the environment.

The heat energy

generated during the combustion of coarse chaff can be used for heat energy

recovery and reuse. The combustion action of the coarse chaff furnace continues,

and coarse chaff is continuously supplied into the furnace. After burning, the

chaff turns into ash and is pushed out of the furnace through the ash discharge

spiral. The continuity of this process ensures stable operation of the

production process and efficient utilization of the coarse bran.

The Husk Furnace manufactured by TW GRANDEUR MACHINERY is a representative of technological innovation. It achieves full utilization of energy resources through multiple technical means such as intelligent control, efficient combustion, and heat energy recovery. Not only does this help save energy costs, it also helps reduce environmental impact. This technology represents the best practices for environmental protection, energy saving and efficiency.

Multifunctional food dryer

Shiitake mushrooms have long been an integral part of Asian cuisine, and their

quality depends on several factors, the most critical of which is the drying

process.

TW

GRANDEUR MACHINERY

's Multifunctional food

dryer is an efficient drying equipment specially designed for mushroom

producers, providing superior drying solutions.

Importance of Multifunctional food dryer: Shiitake mushrooms are an ingredient with a high moisture content and are prone to deterioration and rot if not properly dried.

The drying process can help extend the shelf life of shiitake mushrooms while locking in their nutritional value, ensuring their flavor and texture remain at their best.

In

addition, the appearance of shiitake mushrooms is also affected by the drying

process. High-quality shiitake mushrooms should have a complete shape, bright

color and firm texture.

These features are crucial to attract consumers and gain a competitive advantage

in the market.

Features of

TW

GRANDEUR MACHINERY’s

Multifunctional food dryer:

1.

High efficiency and energy saving The

Multifunctional food dryer adopts advanced drying technology, which can

dry the mushrooms to the required moisture content in a short time while saving

energy to the greatest extent. Our equipment design is enhanced to ensure that

heat energy is not wasted, thus reducing production costs.

2.

Uniform drying Our Multifunctional food dryer

has the advantage of uniform drying, ensuring that each mushroom receives the

same level of heat treatment. This helps eliminate the adverse effects of uneven

moisture on the quality of the mushrooms, allowing each mushroom to maintain

consistent quality.

3.

Automated control

TW

GRANDEUR MACHINERY’s

Multifunctional food dryer is equipped

with an advanced automated control system that can monitor and adjust the

temperature and humidity during the drying process. This ensures stability and

repeatability of the drying process, resulting in improved product consistency.

4.

High-Quality Materials Our

Multifunctional food dryer is made of high-quality materials for superior

durability and reliability. This means you can invest in our equipment with

confidence and benefit from its superior performance in the long term.

Reasons to choose

TW

GRANDEUR MACHINERY:

1.

Excellent customer service We provide excellent customer service with customer

satisfaction as our primary goal. Whether you have any questions about our

Multifunctional food dryer or need

technical support, our team will be happy to assist you.

2.

Professional experience

TW

GRANDEUR MACHINERY

has many years of experience in drying equipment manufacturing, and our

professional knowledge and technology enjoy a high reputation in the industry.

We understand the unique needs of mushroom production and provide our customers

with tailor-made solutions.

3. Success Stories Our Multifunctional food dryer has achieved excellent results in many mushroom manufacturers. Many customers have improved the quality of shiitake mushrooms and achieved increases in production efficiency with the help of our equipment.

E-120

TAKAYAMA High efficiency Grain dryers

In modern

agriculture, rice is an integral part of our diet. However, to ensure a

high-quality rice supply, efficient and reliable drying equipment must be used.

TW GRANDEUR MACHINERY 's TAKAYAMA

High efficiency Grain dryers is the ideal solution for this need.

Working principle of chaff furnace dryer:

H1 temperature control and even baking

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency Grain dryers

achieves uniform baking through temperature control technology. This ensures

that the rice grains are not affected by temperatures that are too high or too

low during the baking process, maintaining their optimal nutritional value.

H2 long-term use and durability

This dryer has a

sturdy design and excellent durability. It operates for a long time and requires

minimal maintenance, saving maintenance costs and time.

H3 is easy to operate

Using

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency

Grain dryers is very simple and does not require complicated operating

steps or special skills. This makes it ideal for agricultural users and

processing plants.

H4 Reduce drying costs

The efficiency of

this dryer means you save energy and costs during the drying process. It can

complete drying tasks quickly and evenly, making your production line more

competitive.

Improve rice quality:

H1 retains nutritional value

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency

Grain dryers preserves the nutritional value of rice grains during the

baking process. This means you can provide healthier, more nutritious rice

grains to your customers.

H2 improves taste

This dryer not only

preserves the nutritional value, but also improves the taste of the rice grains.

cut costs:

H1 Reduce energy consumption

Due to its high

efficiency, TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency Grain dryers

can reduce energy consumption and save your production costs. It’s also more

environmentally friendly.

H2 Reduce labor costs

The easy-to-operate

design means you don’t need a lot of labor to run this dryer. This saves your

human resources costs.

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency Grain dryers

is an amazing piece of equipment that not only improves the quality of rice

grains but also saves production costs. Whether you are an agricultural user or

a food processing plant, this dryer is worth your consideration. Its durability,

ease of operation, and cost-saving benefits will bring tremendous value to your

business.

common problem:

1. What types of rice is this dryer suitable for?

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency

Grain dryers is suitable for various types of grain rice, including white

rice, brown rice and other varieties.

2. What are the maintenance requirements for this dryer?

Due to its sturdy

design, this dryer requires very low maintenance. Keep it in good operating

condition with regular inspection and cleaning.

3. What is its

production capacity?

TW GRANDEUR MACHINERY

's TAKAYAMA High

efficiency Grain dryers has high production capacity

E-300

TAKAYAMA High efficiency Grain dryers

In modern

agriculture, rice is an integral part of our diet. However, to ensure a

high-quality rice supply, efficient and reliable drying equipment must be used.

TW GRANDEUR MACHINERY 's TAKAYAMA

High efficiency Grain dryers is the ideal solution for this need.

Working principle of chaff furnace dryer:

H1 temperature control and even baking

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency Grain dryers

achieves uniform baking through temperature control technology. This ensures

that the rice grains are not affected by temperatures that are too high or too

low during the baking process, maintaining their optimal nutritional value.

H2 long-term use and durability

This dryer has a

sturdy design and excellent durability. It operates for a long time and requires

minimal maintenance, saving maintenance costs and time.

H3 is easy to operate

Using

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency

Grain dryers is very simple and does not require complicated operating

steps or special skills. This makes it ideal for agricultural users and

processing plants.

H4 Reduce drying costs

The efficiency of

this dryer means you save energy and costs during the drying process. It can

complete drying tasks quickly and evenly, making your production line more

competitive.

Improve rice quality:

H1 retains nutritional value

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency

Grain dryers preserves the nutritional value of rice grains during the

baking process. This means you can provide healthier, more nutritious rice

grains to your customers.

H2 improves taste

This dryer not only

preserves the nutritional value, but also improves the taste of the rice grains.

cut costs:

H1 Reduce energy consumption

Due to its high

efficiency, TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency Grain dryers

can reduce energy consumption and save your production costs. It’s also more

environmentally friendly.

H2 Reduce labor costs

The easy-to-operate

design means you don’t need a lot of labor to run this dryer. This saves your

human resources costs.

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency Grain dryers

is an amazing piece of equipment that not only improves the quality of rice

grains but also saves production costs. Whether you are an agricultural user or

a food processing plant, this dryer is worth your consideration. Its durability,

ease of operation, and cost-saving benefits will bring tremendous value to your

business.

common problem:

1. What types of rice is this dryer suitable for?

TW GRANDEUR MACHINERY 's

TAKAYAMA High efficiency

Grain dryers is suitable for various types of grain rice, including white

rice, brown rice and other varieties.

2. What are the maintenance requirements for this dryer?

Due to its sturdy

design, this dryer requires very low maintenance. Keep it in good operating

condition with regular inspection and cleaning.

3. What is its

production capacity?

TW GRANDEUR MACHINERY

's TAKAYAMA High

efficiency Grain dryers has high production capacity

E-500

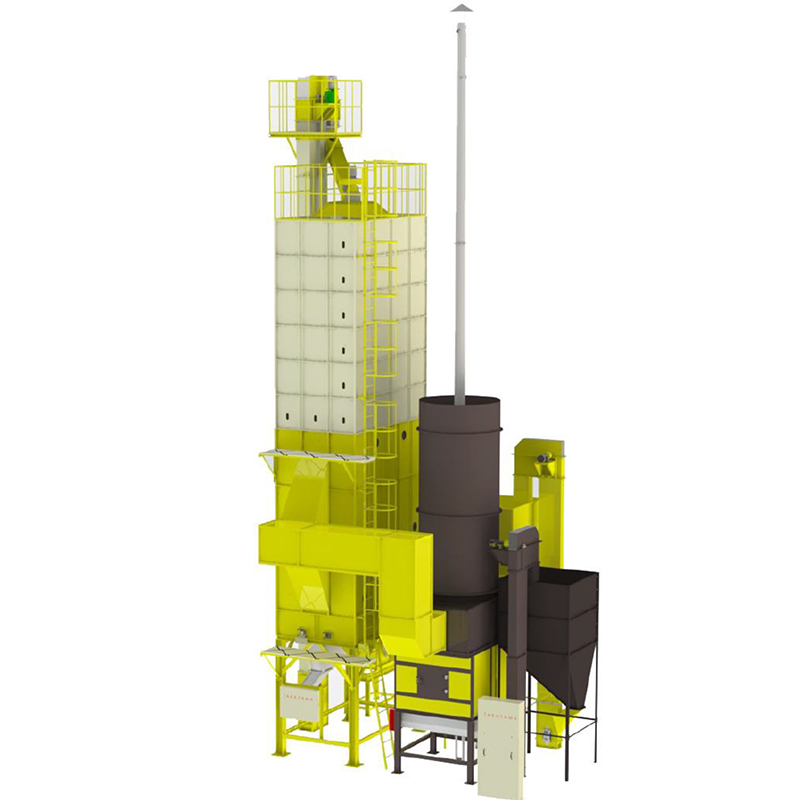

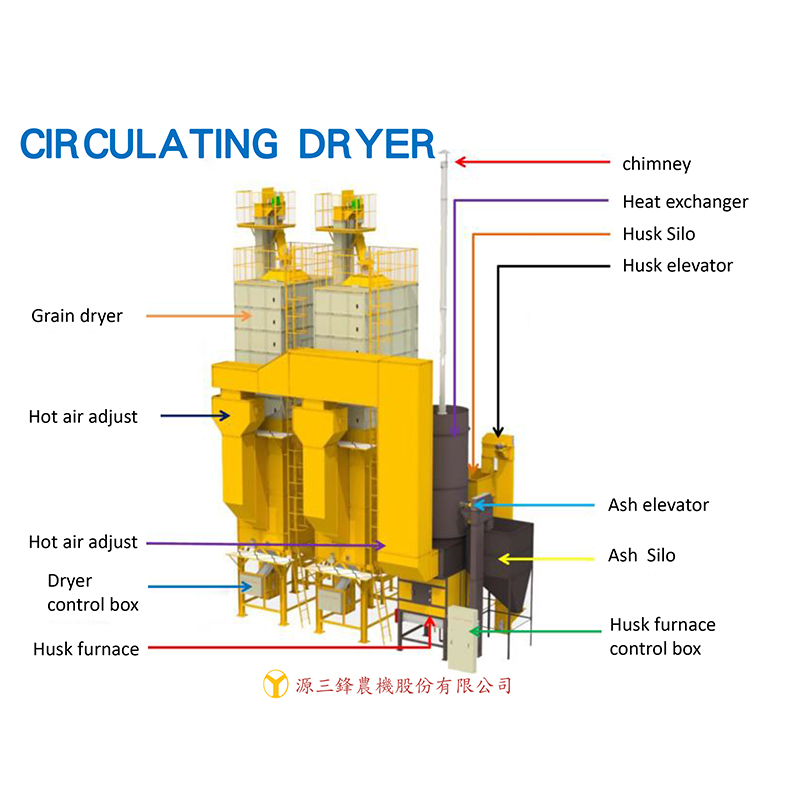

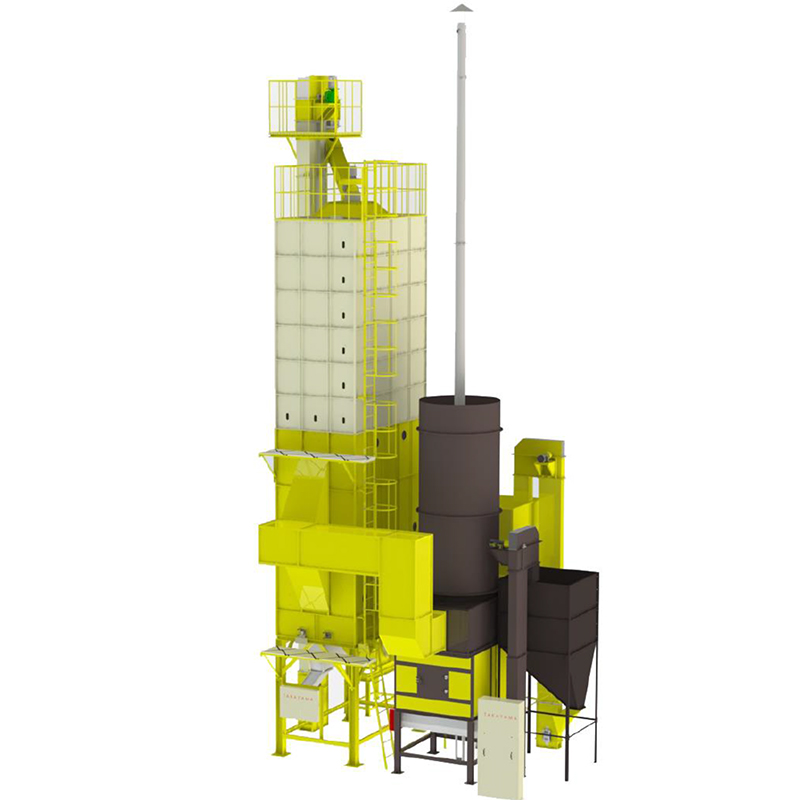

1 to 2 CIRCULATING DRYER

To ensure a high-quality rice supply, efficient and reliable drying equipment is necessary. The 50-ton dryer (1 to 2 CIRCULATING DRYER) produced by TW GRANDEUR MACHINERY Manufacturing is the ideal solution to this demand.

This CIRCULATING DRYER is famous for its excellent temperature control technology. This technology ensures that the rice grains are not affected by temperatures that are too high or too low during the entire baking process. The benefit of this is that it helps maintain the optimal nutritional value of the rice grains, allowing you to serve healthier meals.

This machine has a sturdy design and offers excellent durability. Not only can it run for a long time, but it also requires minimal maintenance, which will save you a lot of maintenance costs and time, making your production line more competitive. In addition, its operation is very simple and does not require complicated operating steps or special skills. This makes it ideal for agricultural users and processing plants. Whether you're an experienced operator or a newbie, it's easy to get started.

TW GRANDEUR MACHINERY 's 1 to 2 CIRCULATING DRYER not only dries efficiently, but also retains the nutritional value of rice grains during the baking process. This advantage means you can offer rice with more nutritional value to your customers, thereby satisfying their demand for healthy food. In addition to preserving the nutritional value, this dryer also improves the texture of the rice grains. After its treatment, the rice will be softer and more delicious, making your food more attractive in the market.

TW GRANDEUR MACHINERY 's 50-ton dryer (1 to 2 CIRCULATING DRYER) is known for its high efficiency and can significantly reduce energy consumption. This not only saves your production costs, but also helps reduce the impact on the environment and is more environmentally friendly. It not only improves the quality of rice, but also saves production costs. Whether you are an agricultural user or a food processing plant, this dryer is worth your consideration. Its durability, ease of operation, and cost savings will provide you with great value. Not only that, it also helps improve product quality and meet customer demand for delicious, nutritious food.

E-500

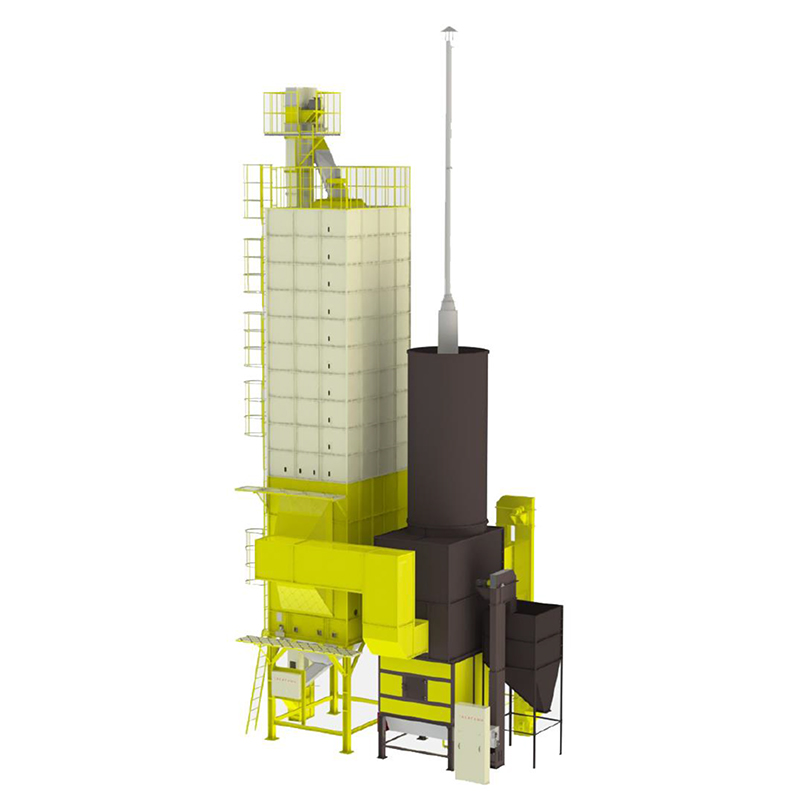

CIRCULATING DRYER

In modern

agriculture, rice is an integral part of our diet. However, to ensure a

high-quality rice supply, efficient and reliable drying equipment must be used.

TW GRANDEUR MACHINERY 's

CIRCULATING DRYER is the ideal solution for this need.

Working principle of chaff furnace dryer:

H1 temperature control and even baking

TW GRANDEUR MACHINERY 's

CIRCULATING DRYER

achieves uniform baking through temperature control technology. This ensures

that the rice grains are not affected by temperatures that are too high or too

low during the baking process, maintaining their optimal nutritional value.

H2 long-term use and durability

This dryer has a

sturdy design and excellent durability. It operates for a long time and requires

minimal maintenance, saving maintenance costs and time.

H3 is easy to operate

Using

TW GRANDEUR MACHINERY 's

CIRCULATING DRYER is very simple and does not require complicated operating

steps or special skills. This makes it ideal for agricultural users and

processing plants.

H4 Reduce drying costs

The efficiency of

this dryer means you save energy and costs during the drying process. It can

complete drying tasks quickly and evenly, making your production line more

competitive.

Improve rice quality:

H1 retains nutritional value

TW GRANDEUR MACHINERY 's

CIRCULATING DRYER preserves the nutritional value of rice grains during the

baking process. This means you can provide healthier, more nutritious rice

grains to your customers.

H2 improves taste

This dryer not only

preserves the nutritional value, but also improves the taste of the rice grains.

cut costs:

H1 Reduce energy consumption

Due to its high

efficiency, TW GRANDEUR MACHINERY 's

CIRCULATING DRYER

can reduce energy consumption and save your production costs. It’s also more

environmentally friendly.

H2 Reduce labor costs

The easy-to-operate

design means you don’t need a lot of labor to run this dryer. This saves your

human resources costs.

TW GRANDEUR MACHINERY 's

CIRCULATING DRYER

is an amazing piece of equipment that not only improves the quality of rice

grains but also saves production costs. Whether you are an agricultural user or

a food processing plant, this dryer is worth your consideration. Its durability,

ease of operation, and cost-saving benefits will bring tremendous value to your

business.

common problem:

1. What types of rice is this dryer suitable for?

TW GRANDEUR MACHINERY 's

CIRCULATING DRYER is suitable for various types of grain rice, including white

rice, brown rice and other varieties.

2. What are the maintenance requirements for this dryer?

Due to its sturdy

design, this dryer requires very low maintenance. Keep it in good operating

condition with regular inspection and cleaning.

3. What is its

production capacity?

TW GRANDEUR MACHINERY

's

CIRCULATING DRYER

has high production capacity