TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk Furnace

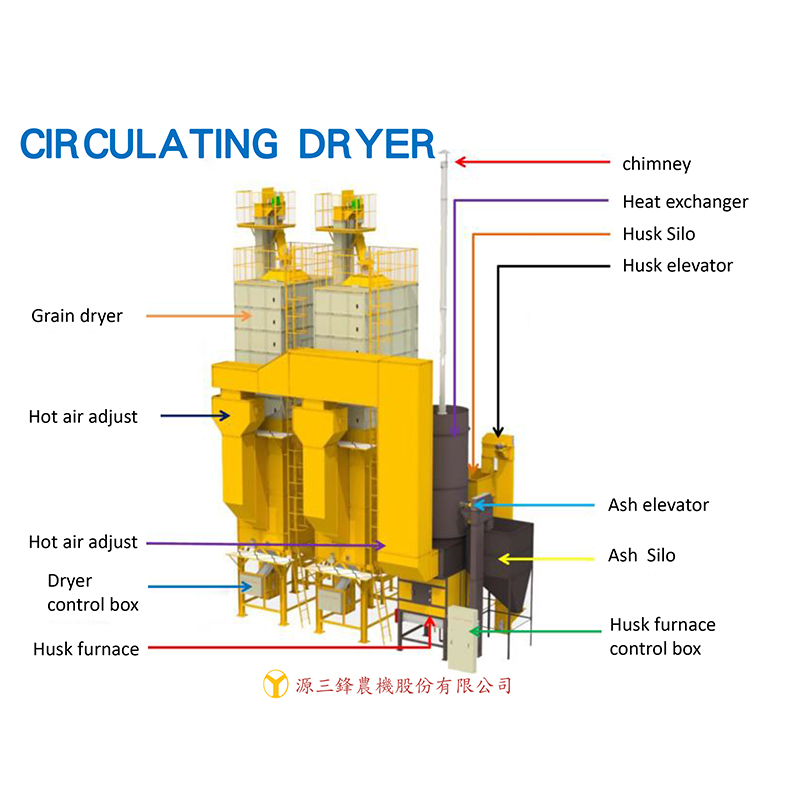

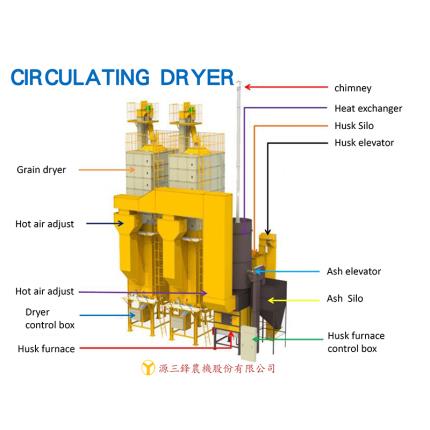

Rice husk furnace dryer

Heat-conducting element design features extra powerful heating efficiency.

The working principle of High-tech Grain Dryer and Husk Furnace:

H1 temperature control and even baking

TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk Furnace

achieve uniform baking through temperature control technology. This ensures that

the rice grains are not affected by temperatures that are too high or too low

during the baking process, maintaining their optimal nutritional value.

H2 long-term use and durability

This dryer has a sturdy design and excellent durability. It operates for a long

time and requires minimal maintenance, saving maintenance costs and time.

H3 is easy to operate

Using TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk

Furnace is very simple and does not require complicated operating procedures

or special skills. This makes it ideal for agricultural users and processing

plants.

H4 Reduce drying costs

The efficiency of this dryer means you save energy and costs during the drying

process. It can complete drying tasks quickly and evenly, making your production

line more competitive.

Improve rice quality:

H1 retains nutritional value

TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk Furnace

can retain the nutritional value of rice grains during the baking process. This

means you can provide healthier, more nutritious rice grains to your customers.

H2 improves taste

This dryer not only preserves the nutritional value, but also improves the taste

of the rice grains.

cut costs:

H1 Reduce energy consumption

Due to their high efficiency, TAKAYAMA High-tech Dryer Indirect air heating &

high Efficiency Husk Furnace can reduce energy consumption and save your

production costs. It’s also more environmentally friendly.

H2 Reduce labor costs

The easy-to-operate design means you don’t need a lot of labor to run this

dryer. This saves your human resources costs.

TAKAYAMA High-tech Dryer Indirect air heating & high Efficiency Husk Furnace

are amazing pieces of equipment that not only improve the quality of rice

grains, but also save production costs. Whether you are an agricultural user or

a food processing plant, this dryer is worth your consideration. Its durability,

ease of operation, and cost-saving benefits will bring tremendous value to your

business.

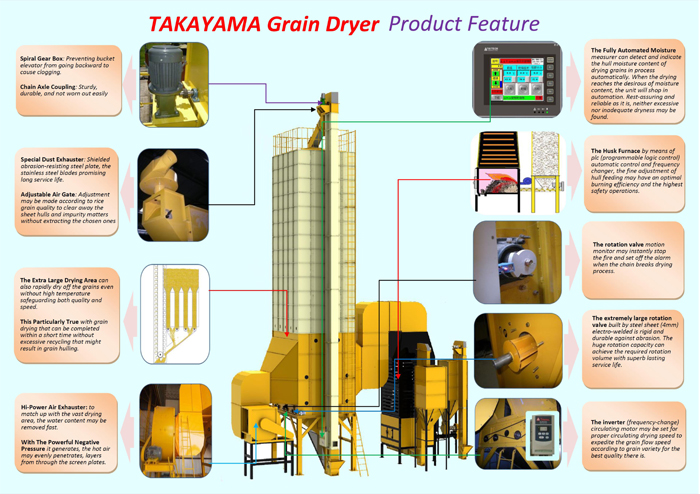

Features

| 1. | No machine stop in necessary during extended period of harvest Season. |

| 2. | Heat-conducting element design features extra powerful heating efficiency. |

| 3. | The extra large heat-conducting area ensures the highest rate of utilization of heating energy. |

| 4. | The duo-inverter design of material feeding and wind blowing promises the most perfect combustion. |

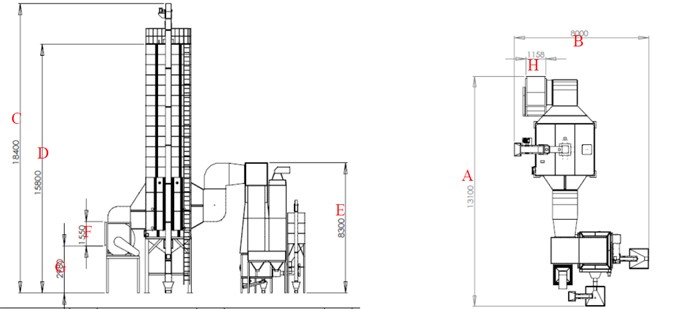

| Model | Capacity/ton | Machine installation dimensions(30t, yellow),(50t,blue) | ||||||||

| Paddy | Corn | A | B | C | D | E | F | G | H | |

| 12tons | 4~12 | 5~14 | 9100mm | 2900mm | 11500mm | 9600mm | 6900mm | 780mm | 1979mm | 680mm |

| 30tons | 12~30 | 15~35 | 11100mm | 7000mm | 14000mm | 12000mm | 7500mm | 885mm | 1092mm | 660mm |

| 50tons | 20~50 | 25~58 | 13100mm | 8000mm | 18400mm | 15800mm | 8300mm | 1550mm | 2980mm | 1160mm |

| Model | 12tons A25-xx-120+Fed | 30tons C45-xx-300+Fed | 50tons D65-xx-500+Fed | |||||||

| Holding Capacity/ton | Paddy | 4~12 | 12~30 | 20~50 | ||||||

| Paddy | 5~14 | 15~35 | 25~58 | |||||||

| Dry layer height | 3000mm | 3000mm | 3000mm | |||||||

| Dryer Exhaust fan horsepower | 15Hp | 25Hp | 40Hp | |||||||

| Max. Thermal Energy (kcal/hr) | 480,000kcal/hr | 800,000kcal/hr | 1280,000kcal/hr | |||||||

| Max. Husk Consumption (kcal/hr) | 150kg/hr | 250kg/hr | 400kg/hr | |||||||

| Power Consumption | Dryer | 14.2KW/19HP | 23KW/31HP | 36.5KW/48.5HP | ||||||

| Husk feed | 0.38KW/0.5HP | 0.38KW/0.5HP | 0.38KW/0.5HP | |||||||

| Help the combustion fan | 2.25KW/3HP | 2.25KW/3HP | 3.75KW/5HP | |||||||

| Help the combustion fan | 1.5KW/2HP | 1.5KW/2HP | 2.25KW/3HP | |||||||

| Help the combustion fan | 18.5KW/24.5HP | 27KW/36.5HP | 42.5KW/56.5HP | |||||||

| Drying Rate (Paddy) | 1.0-3.0%/hr | 1.0~3.0%/hr | 1.0~3.0%/hr | |||||||

| Biomass Fuel | Rice husk, Coconut shell, corncob, Waste wood, such as agricultural wastes | |||||||||

| Control System | Computerized Control With Touch Screen | |||||||||