YRM-15,30

Cereal Whitening Machine

Cereal Whitening Machine, is a

professional food processing equipment designed to ensure the quality and

appearance of cereals. This kind of equipment is usually used to grind grains to

achieve the desired whitening effect.

A key feature of Cereal Whitening Machine is in-frame scrolling. This is

a method of grinding grains, which mainly assembles grinding iron rollers and

spiral iron rollers. The two iron rollers rotate at different speeds, with the

inner frame and rubber plate rotating more slowly. Rubber plates are fixed to

the inner frame to stop the grain flow while ensuring an even glossy surface on

the grain. In addition, the gap of the rubber plate can be adjusted as needed,

ranging from 1mm to 60mm.

The Cereal Whitening Machine is equipped with a unique air jet system

that achieves multiple functions by blowing air from the fan to the grinding

chamber. First, it prevents the temperature of the grain from rising, which is

crucial to maintaining grain quality. Secondly, the air jet system prevents bran

from adhering to the mesh of the grinding equipment, thereby ensuring that the

grains are evenly whitened.

Cereal Whitening Machine is very simple to operate and easy to maintain. This

means that even average workers can easily operate the equipment, ensuring

smooth execution of the production process.

TAKAYAMA Cereal Whitening Machine uses a grinding roller that is

different from traditional production methods. These grinding rollers are

rigorously formed and heat treated to give them longer life and higher

durability. This means you can use this device for a long time without having to

worry about the wear and tear of a typical whitening machine.

Cereal Whitening Machine is a professional equipment that ensures grain

whitening. Its grinding features, air jet system, easy operation and superior

grinding rollers make it an indispensable tool in the food processing industry.

Whether you run a food processing business or a home kitchen, this equipment

ensures the best quality and appearance of your cereals.

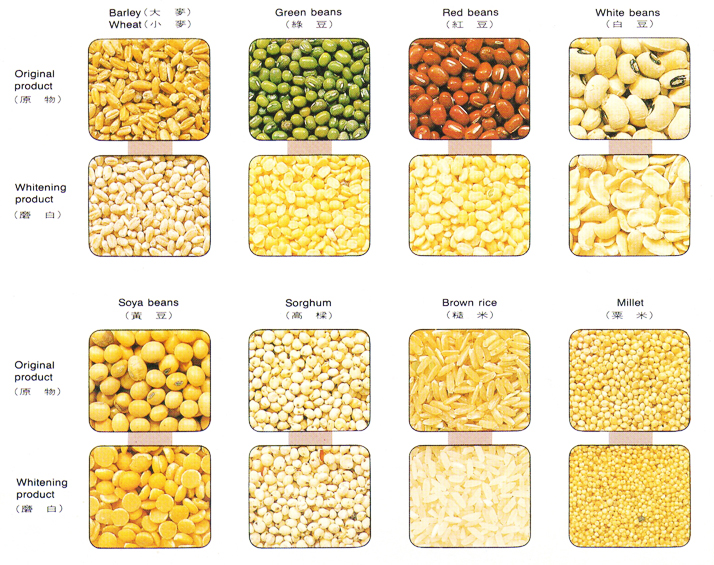

Cereal Whitening Machine is generally suitable for most grains, including

rice, wheat, corn, etc.

Although the Cereal Whitening Machine is simple and easy to use, regular

maintenance is recommended to ensure it performs well. This includes cleaning,

lubricating and replacing worn parts. The speed can be adjusted according to

different grains and requirements to ensure the best whitening effect.

Features

ABRASIVE-TYPE SPECIAL: INNER FRAME ROLLING

Cereal Whitening Machine, which assembled abrasive roller and steel wire roller in the center of milling chamber. Both of them rub with rotary inner frame each other. But abrasive roller and steel wire roller rotary with high speed, inner frame and rubber plates rotary with low speed. Rubber plates locked on the inner frame in order to stop the brown cereal flow and to get a uniform whitening and luster. If the rubber plates worn out, you can adjust it from 1mm to 60mm. UNIQUE JET AIR SYSTEM

Jet air is blown from the fan to the milling chamber, functioning not only to prevent the temperature of the cereal grains from rising but also to remove bran sticking to the whitened cereal. EASY OPERATION

This machine is a masterpiece. It is very different from other countries made. Operation is very easy, requiring no previous training. SUPERIOR ABRASIVE ROLLER

Unlike conventional methods of production, the YUAN SAN FON abrasive rollers are manafactured with strict forming and heat treatment, giving them extra-high durability and sharpness. Dull edge conventional rollers means excess pressure on the cereal grains during whitening potential of the abrasive- type process.

Specification

| Model | Required Power | Input Capacity | N.W. | G.W. | Overall Dimension L x W x H |

| YRM-15 | 20HP | 1000KGS | 810KGS | 970KGS | 1600 x 1035 x 1137 mm |

| YRM-30 | 40-50HP | 2000-2500KGS/HR | 1040KGS | 1226KGS | 2280 x 1035 x 11 mm |